Tel: 01430 861893

for tomorrow's cutting edge technology - today

PCD Tooling Solutions, offers you first class manufacturing and sharpening services for all polycrystalline diamond tipped machine tools. We’re based in York, and cover the whole of the UK.

Our PCD sharpening capabilities are second to none. We work to incredibly fine tolerances and all tools are quality checked, balanced and certificated before despatch.

Not only do we source new tools from around the world, we can also design and manufacture PCD tools to meet your precise specifications.

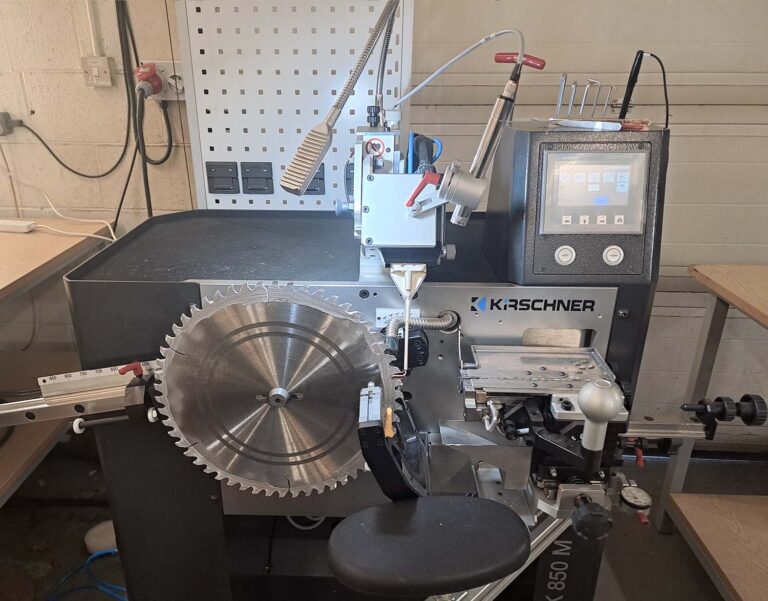

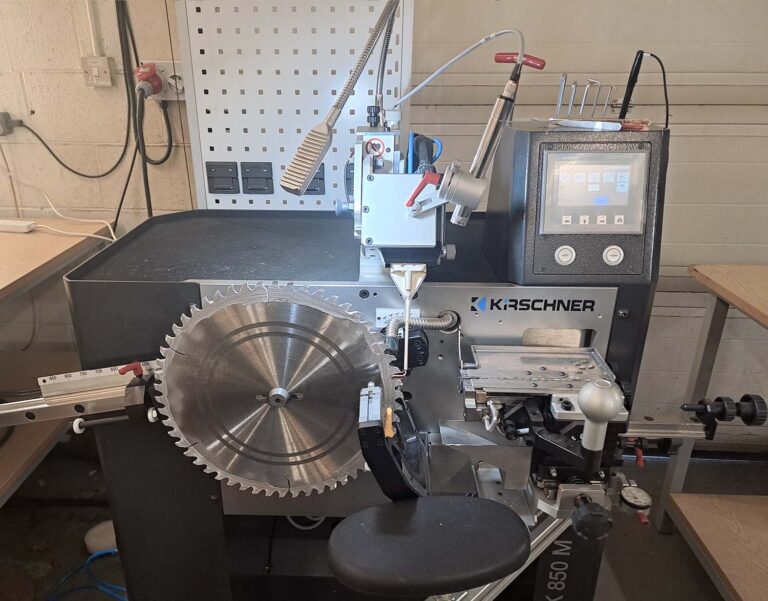

We’ve invested heavily in plant over the years, and our workshop floor now hosts an impressive range of machinery from the biggest names in the business.

Call today on 01430 861893 or choose one of the buttons below to send us a mail

NEW: STATE OF THE ART LASER EROSION MACHINE INSTALLED

With the recent installation of the Diarex Laser Erosion machine PCD now offers the full range of technologies.

Setting new standards in cutting edge quality, accuracy and consistency. For the most demanding ultra hard cutting tools. the most complex tools can be serviced and manufactured . For all materials across all manufacturing areas that require cutting tools.

Why choose us?

PCD Tooling Solutions Ltd was formed in 2008 but our experience in the tooling industry goes back much further – over 40 years! That makes us one of the longest established PCD tooling specialists in the UK. Our knowledge is second to none and we have partners and specialist suppliers all over the world.

What’s more, if we can’t find the exact tooling you’re after, we can design and manufacture tools in-house to your precise specification.

Through our strategy of continual investment, we now operate a suite of industry leading sharpening machines. Every single tool is fully inspected to the finest of tolerances and then perfectly balanced to Haimer standards. If that’s not enough, we’re also very proud of being a family business. Business is business, but with us, our reputation is personal.

Why use PCD tools?

It’s an open secret in the manufacturing industry that Polycrystalline Diamond (PCD) tipped tools give a cleaner cut and maintain their ultra sharp cutting edge much, much longer than traditional TCT tools.

If you rely on saw blades, router cutters, hoggers etc to keep your business running, you should consider switching to PCD like many of our customers already have – and they’ve never looked back!

Yes, the upfront cost of the tools is higher than TCT, but there are huge savings to made in the long run. If you’re already running close to capacity, you’ll find the massively reduced downtime a god-send, increasing productivity immediately. Plus the quality of cut should ensure reduced wastage, fewer returns and happier customers.

The PCD Sharpening specialists

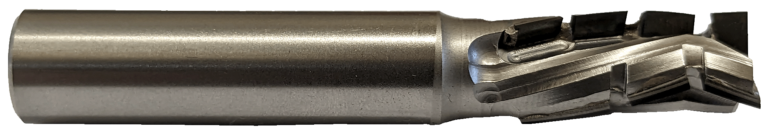

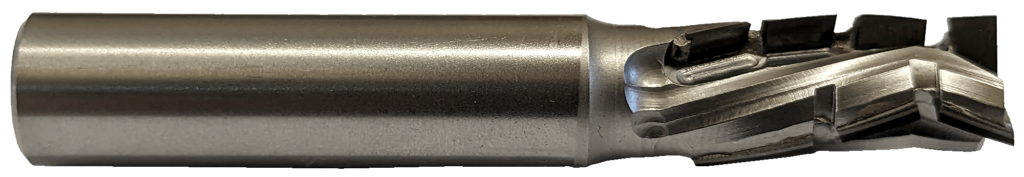

Polycrystalline diamond machine tools are strong and built to last, but as with all tools, keeping them sharp increases efficiency. PCD Tooling Solutions offers first-class sharpening services for all of your PCD tools.

Using the latest EDM CNC technology we are able to refine the quality of any existing saw blade, router cutter or hogger to your exact requirements.

We are one of only a few companies in the UK to sharpen and manufacture PCD machine tools, and we are committed to providing you with thigh the highest quality of service and honest advice.

Call us to discuss your requirements and specifications, then send us your machine tools.

We’ll inspect them first and if all is well, you’ll can expect them back, good as new within 7-10 working days.

If we think your PCD tools are not going to perform for you much longer we will let you know and advise accordingly. We are able to supply a range of new tools.

For more information on our sharpening services call us today on 01430 861893.

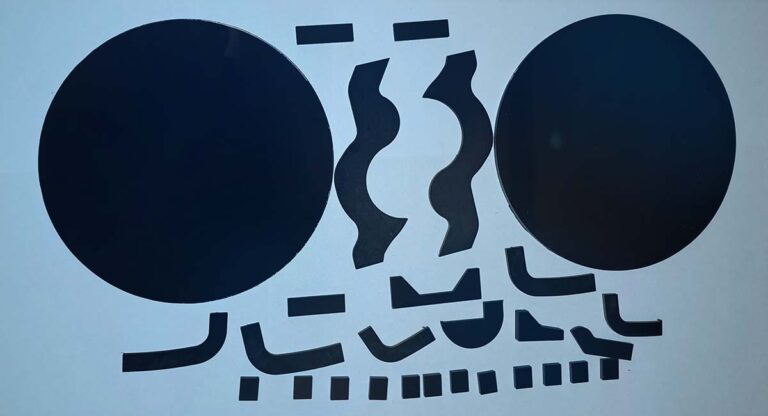

PCD Blanks cut in-house

Here at PCD Tooling Solutions we can cut PCD blanks to any form, shape or size, entirely in-house!

If your tools are showing signs of tip damage but are otherwise structurally sound, we can replace the PCD tips in-house, saving you valuable time with no supply side downtime.

We can cut to any form, shape or size and then secure them to your tools via induction brazing with incredible precision.

New Tools

Whether you're replacing a worn tool or investing in PCD for the first time, we can help you.

HIGH QUALITY TOOLS

We offer top-quality PCD saw blades, router cutters, planer/jointing blocks and laminate flooring systems tools, sourced from trusted suppliers all over the world.

The quality of your product can be negatively affected by using inefficient tools. Not only that, your machinery will be worn down faster as the bearings take all the strain.

Upgrading to PCD machine tools means less hassle, an improved product and a significant increase in capacity – saving you money over the long term.

Bespoke Tool Design

We also offer bespoke blades if you have a machine with specific requirements.

We’ll work with you to design and manufacture in-house, the precise machine tool you need.

Specials

We can design and supply any profile tools to customer specification in ROUTER, CIRCULAR BLOCK or HOGGER format.

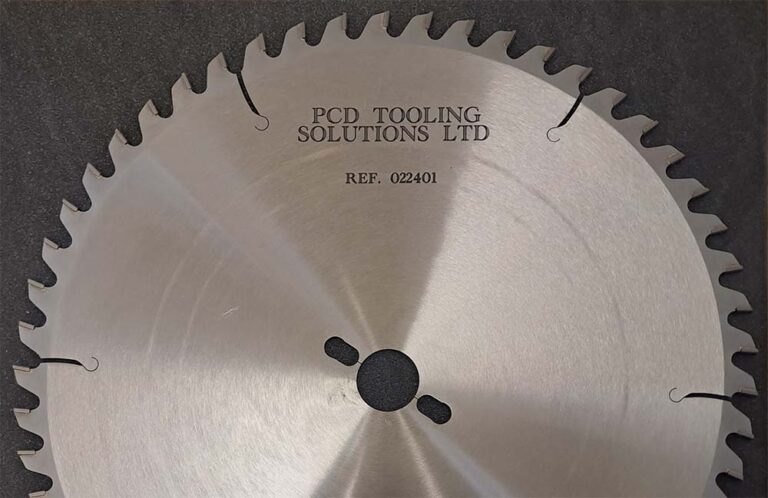

Saw Blades

Something of a speciality here at PCD Tooling Solutions, not only can we sharpen your existing blades, we’re probably the only British company who can also manufacture them to your specification.

- Any size up to 600mm diameter

- Any tooth number

- Any form

- For cutting any material

Workshop and Plant List

It’s taken many years of investment to build up this impressive stable of class leading machinery.

So, what exactly is PCD?

PCD or Polycrystalline Diamond is a synthetic diamond grain used for its incredible strength and resistance.

With diamond being one of the strongest materials on the planet, PCD tipped tools provide a sharper and more efficient cutting or abrasive edge.

PCD uses micron-sized diamond particles which are sintered together at extreme temperatures with a metallic catalyst. The metal and PCD particles are then bonded on top of a layer of tungsten carbide.

So, a PCD tipped tool is a composite material tool with the resiliency of tungsten and the abrasive resistance and conductivity of diamond. Together, this makes for an effective, hardwearing and versatile cutting and drilling tool.

PCD tipped tools are replacing existing TCT tools due their greater lifespan, excellent finish and downtime savings.

If you want to learn more about how switching to PCD tools can help your business, please get in touch.

PCD Tooling Solutions are ideally located near York with easy access to the M62 corridor

Unit 1F Skiff Lane Industrial Estate, Holme-on-Spalding Moor, York, East Yorkshire. YO43 4BB

Call today on 01430 861893 or choose one of the buttons below to send us a mail

Providing you with an exceptional PCD sharpening and PCD manufacturing service